CNC Lathe

The construction of the plasma cutter completed successfully aroused the desire to implement further projects from the automation area. For several years we have been struggling for example with the production of sleeves used in the saddlebag supports or all kinds of distances based on a steel bar. We are talking about many thousands of pieces, which until now had to be made by one of us in the so-called ‘free time’.

Thus came time for the CNC lathe. The plan included the purchase of a classic lathes “manual” and rework it to maintenance-free machine. After analyzing the market offer the choice fell on the local device distributor that meets our minimum dimensions necessary for subsequent processing.

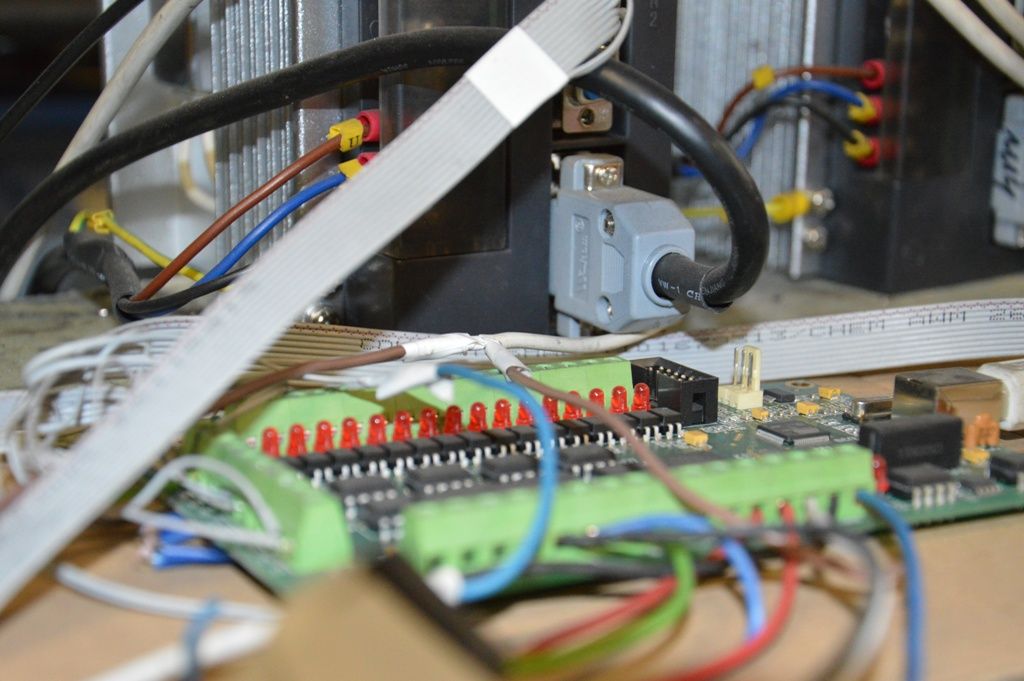

Applied in modernization:

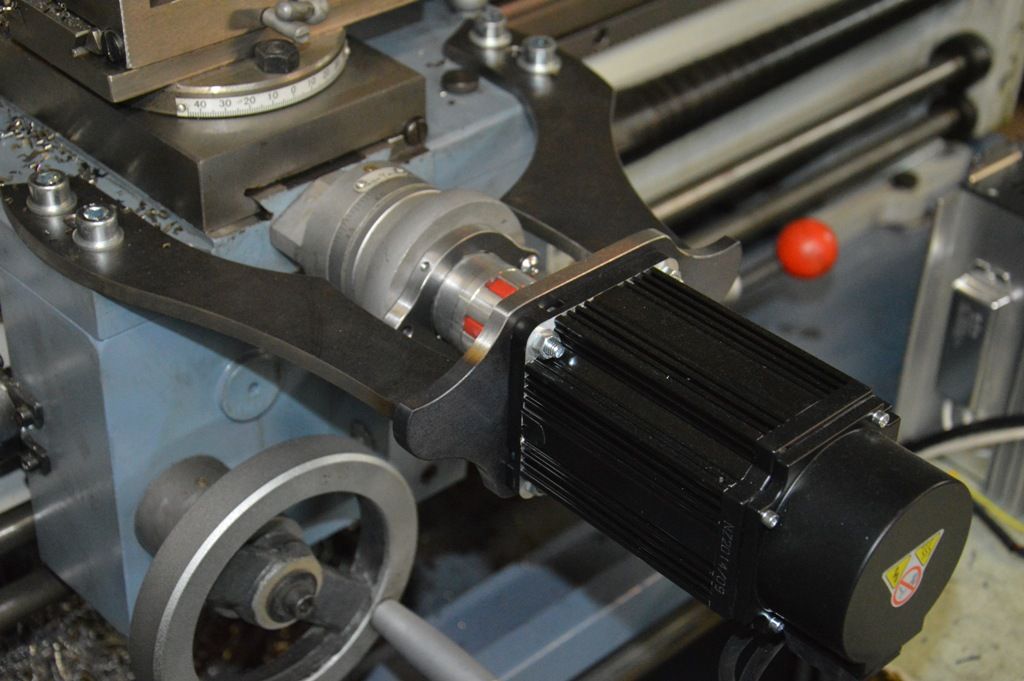

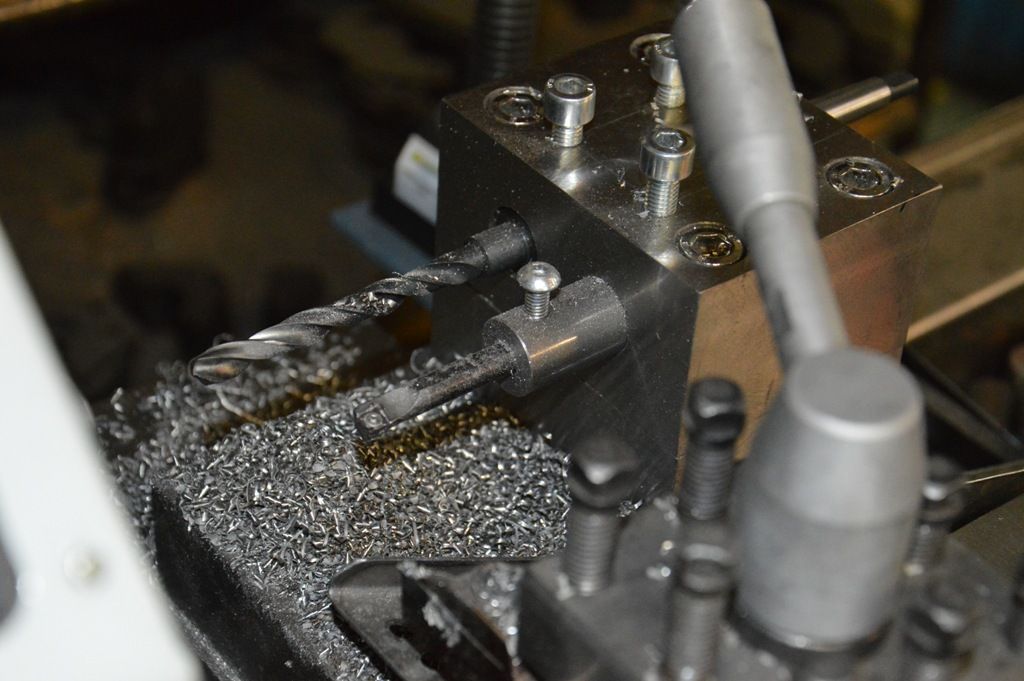

1. Servo motors that drive the two axes X and Z (meaning quieter and more accurate than stepper ones used in the cutter plasma – but several times more expensive)

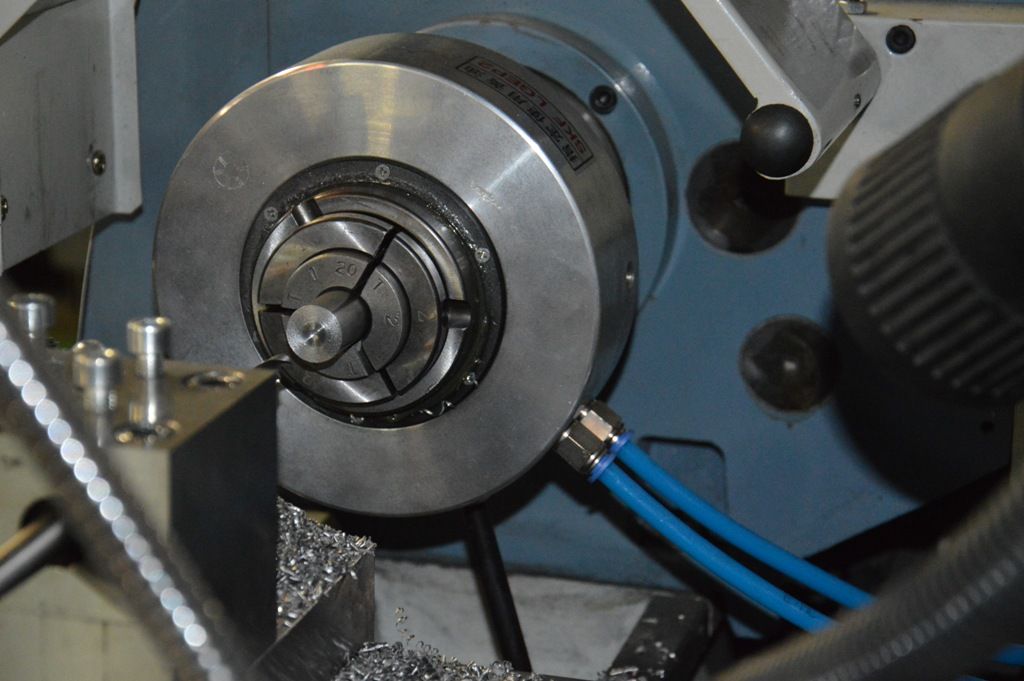

2. The pneumatic rotary chuck, which can be operated by computer,

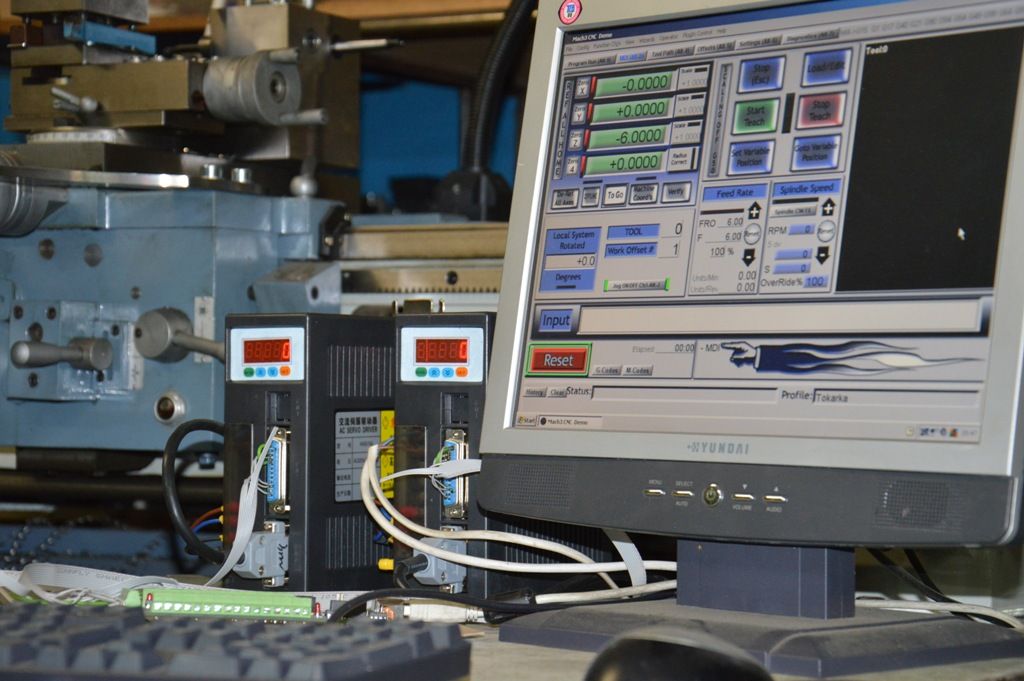

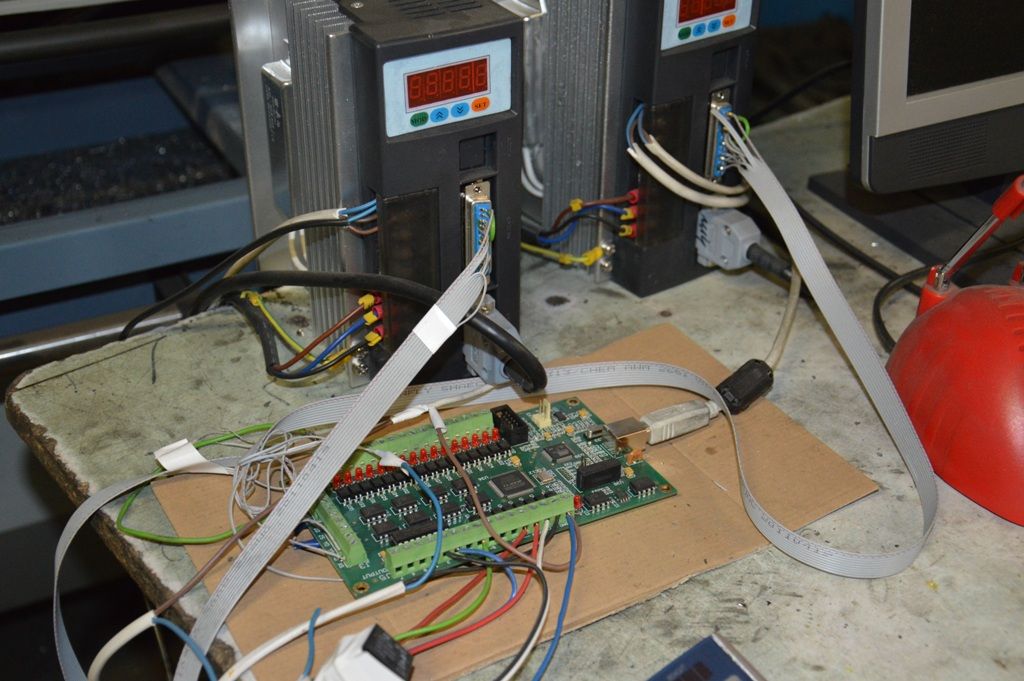

3. Control electronics components, a series of more or less complex parts manufactured in our company, a computer with appropriate software.

After 3 months of work was created the device which fully meets our expectations. In the pictures below we present the lathe still in draft.

I invite you to watch the movie with the work of our next ‘baby’- automatic lathe: