Custom CNC Plasma Cutter

RoadStyler is mainly motorcycles, I would even say ‘motorcycle over everything’. But sometimes one gets embraced by the need to compete well in another field. And so the idea of creating another ‘strange’ device was born. After a custom bicycle came time for the ‘custom’ CNC plasma cutter. I could do just a device for cutting steel, but I would not be me if I hadn’t little modified this device.

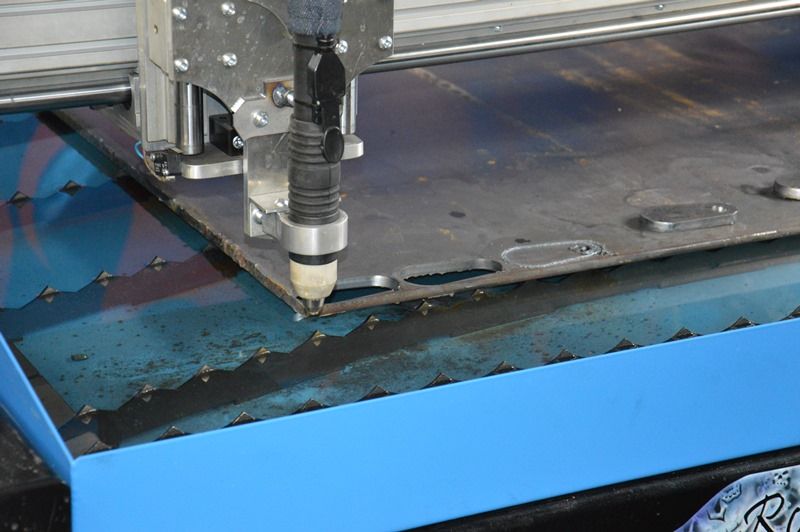

For the uninitiated, a CNC plasma cutter is such a machine, which cuts required shapes from a sheet of steel using a burner. The movement of the burner is controlled by an electronics device connected to the computer. Obviously this is a very rough translation and you should not treat it as a definition – it is only a similar outline of what would soon arise.

Starting a project (with the assumption being fairly simple) I did not expect to meet so many surprises that would effectively lengthen the time of its implementation. But gained in this way the knowledge resulting from the increasingly overcome unforeseen traps – is simply priceless.

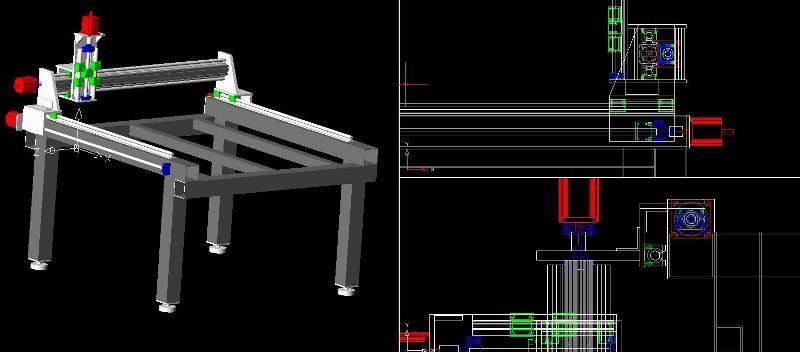

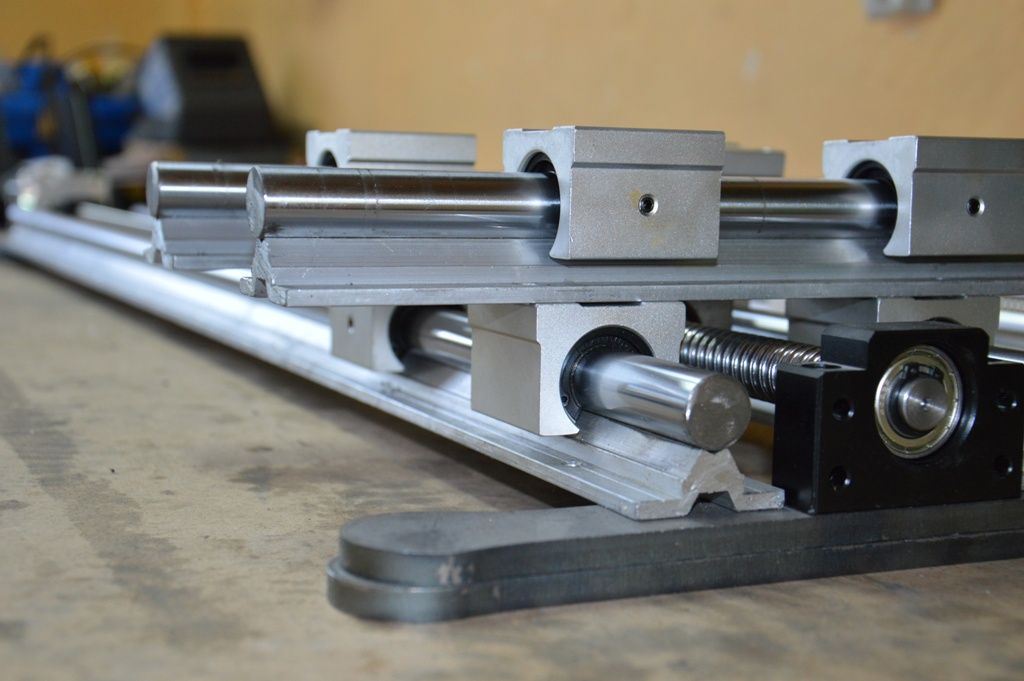

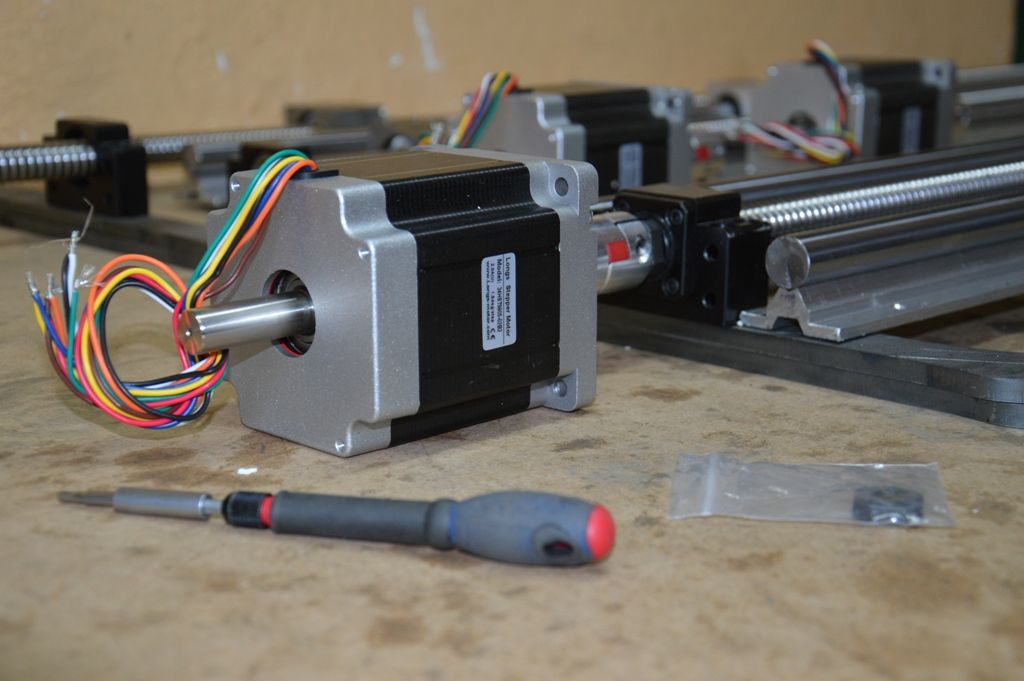

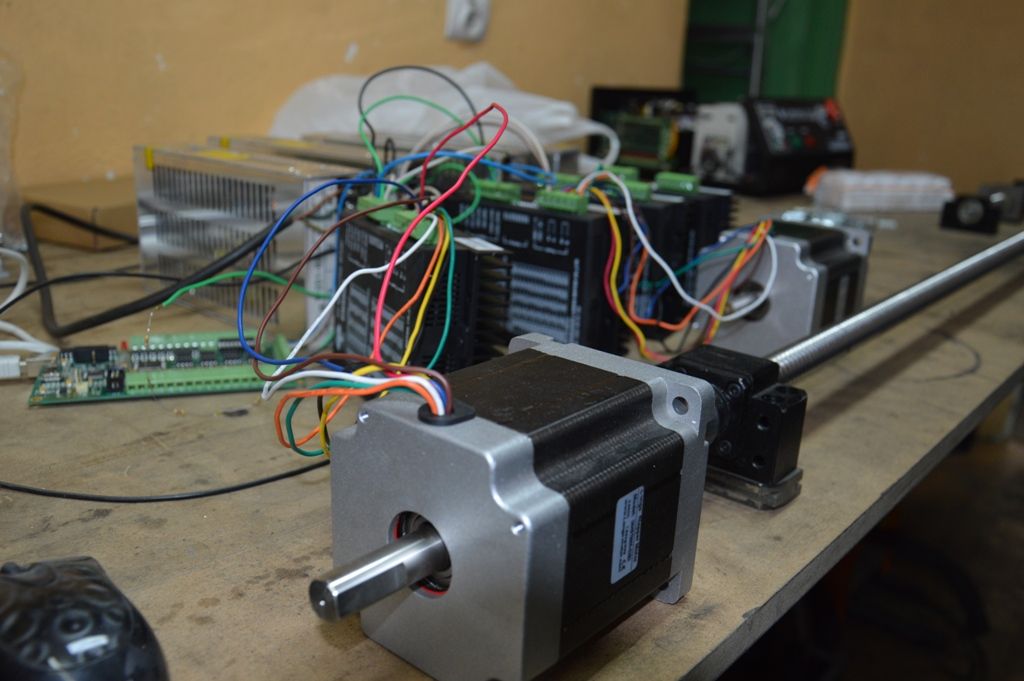

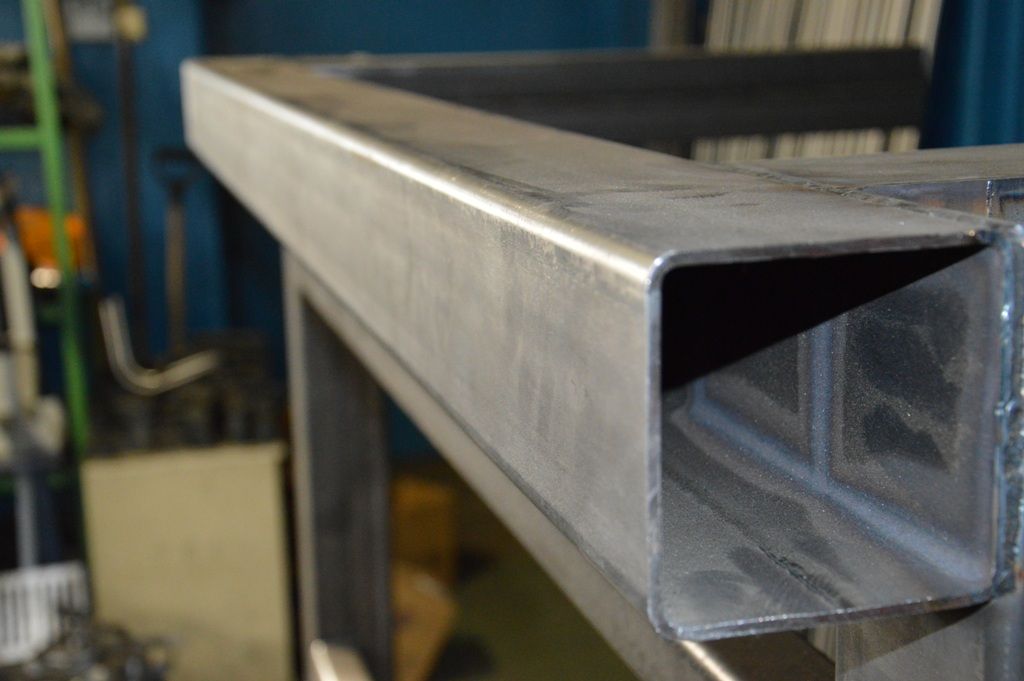

Let’s do it. Days spent waiting for the corresponding elements, measuring, combining the what and why have resulted in a project that seemed to be the most optimal and technically easy for later execution. At the beginning – the shopping of core moving parts and other construction components.

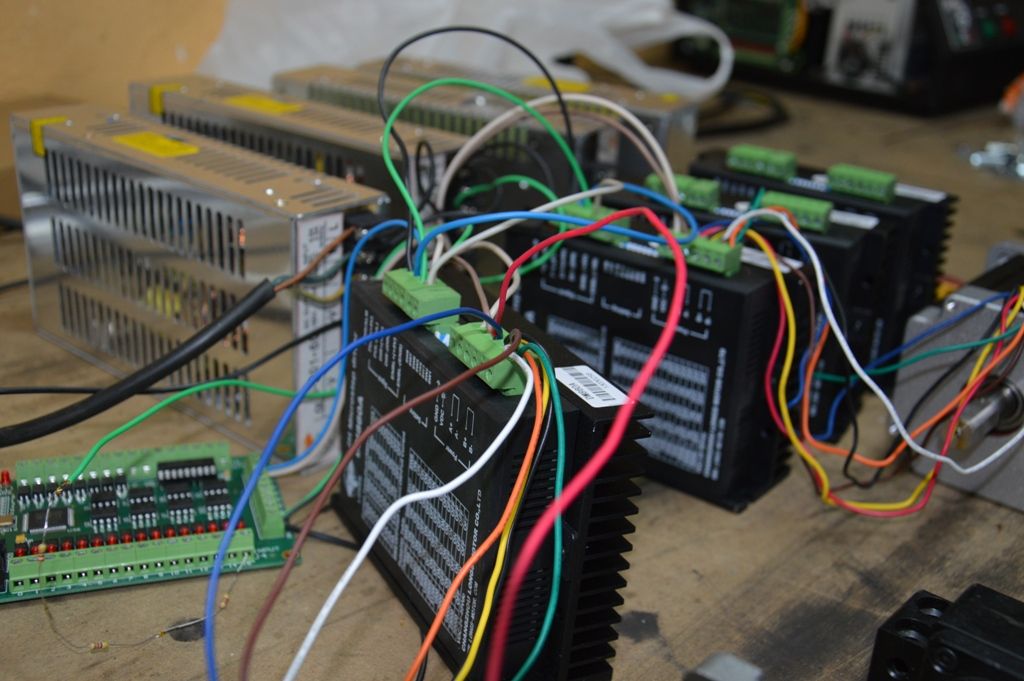

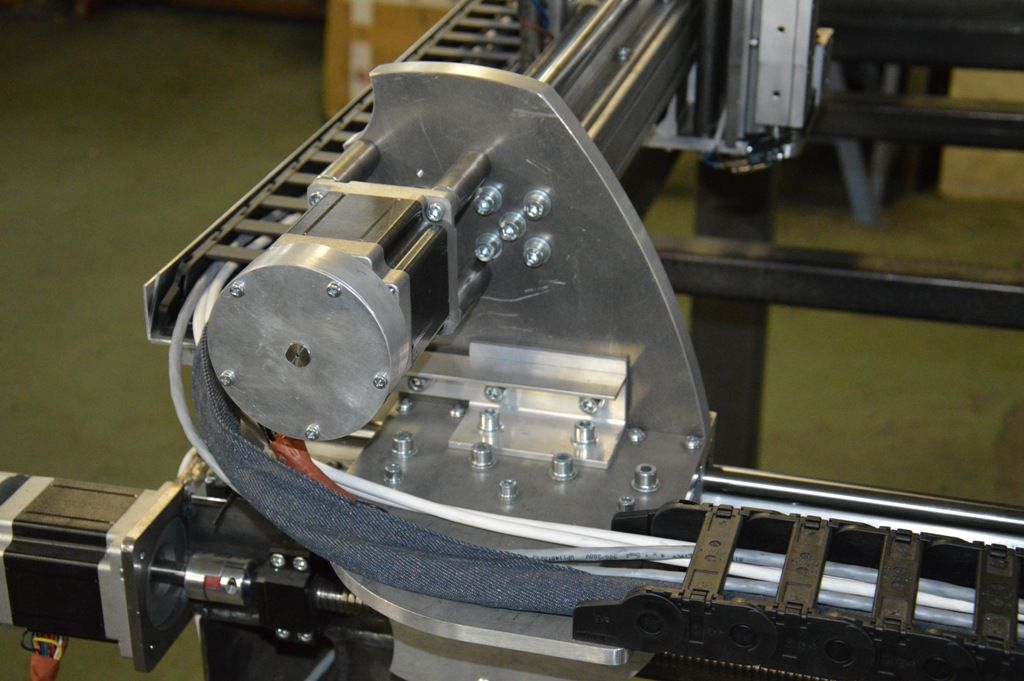

After collecting the relevant elements came time for the welding of the supporting structure (table) and the milling of aluminum structural elements. I was also to assemble and test the control electronics.

After a few weeks I got a general outline of the machine to the delusion reminiscent of my project :). The first movement attempts were successful, but also showed weaknesses of equipment that had to be eliminated. And so a few days (or maybe weeks) lost to find solutions and amendments.

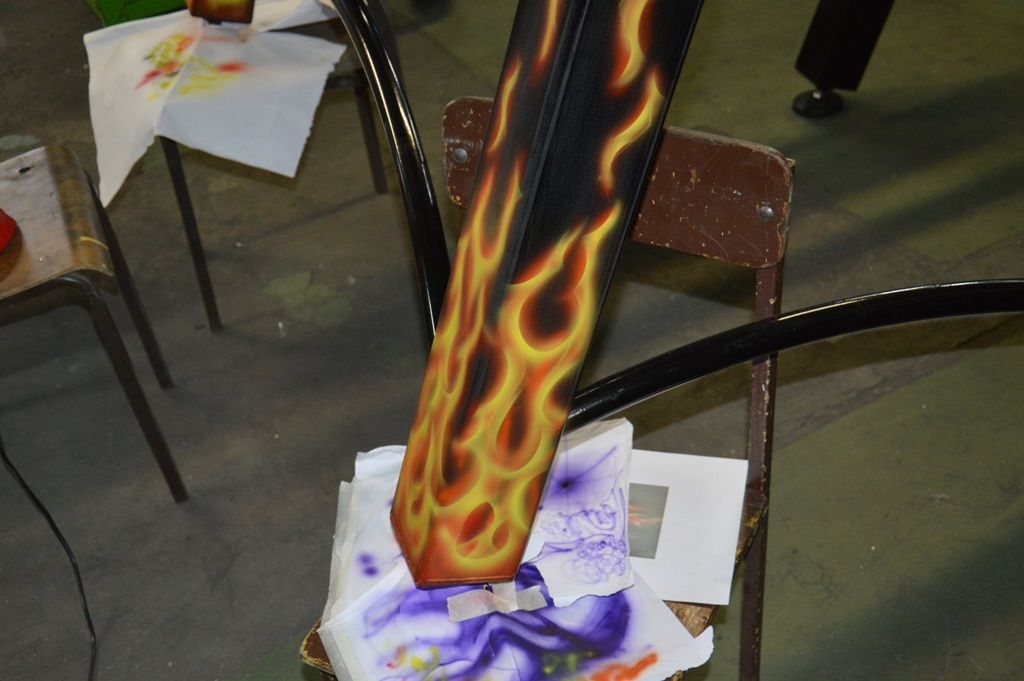

Since it was supposed to be a custom machine, it could not be done without airbrush. This time made by my own. Maybe I did not reach the heights of graphics, but considering the technical approach and lack of experience – finally it came out pretty good.

It took a few months from concept to completion. The device is efficient – it burns details as intended. It looks interesting, but can you call them “custom”? Only you can judge it.

I invite you to watch the movie of the working machine: