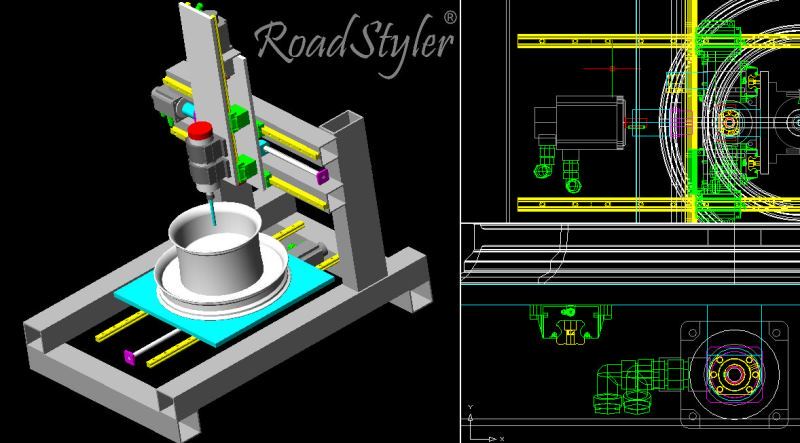

CNC Milling Machine

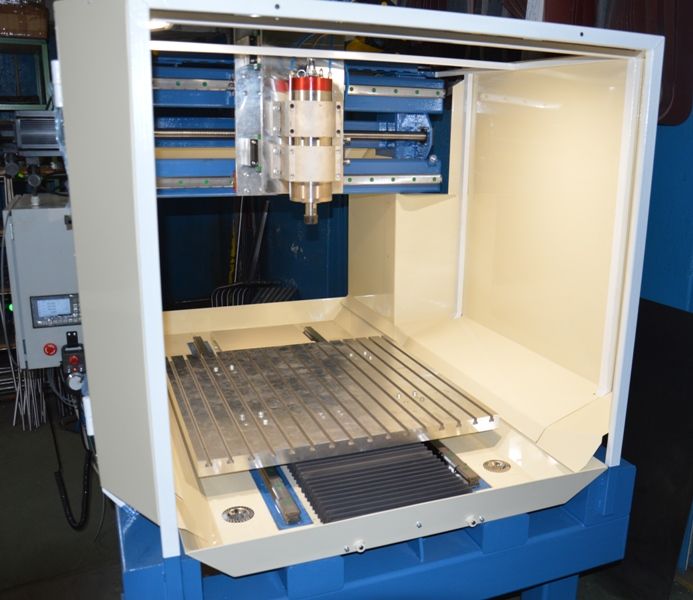

Automation is an incredibly addictive “fun”, so with the end of the motorcycle season I decided to start working on the next device. In October 2016, I sketched the initial design of a CNC milling machine – a machine whose task is to cut 3D aluminum elements. Since one of the components made with it will be custom motorcycle wheels, I needed a machine with a large working space – 800x800x500mm.

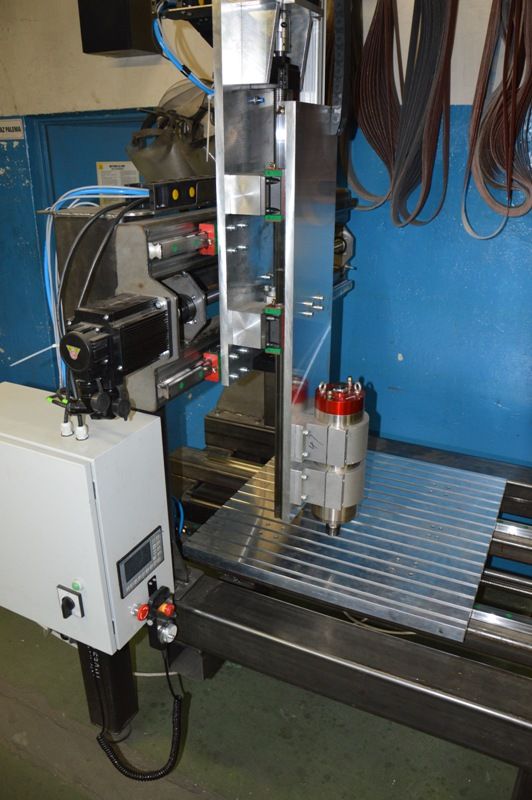

In parallel with the design, it was necessary to send out the first orders for materials necessary for its implementation. Soon servo motors, controllers, spindle and control module arrived. This time I gave up control of a PC computer for a dedicated CNC module.

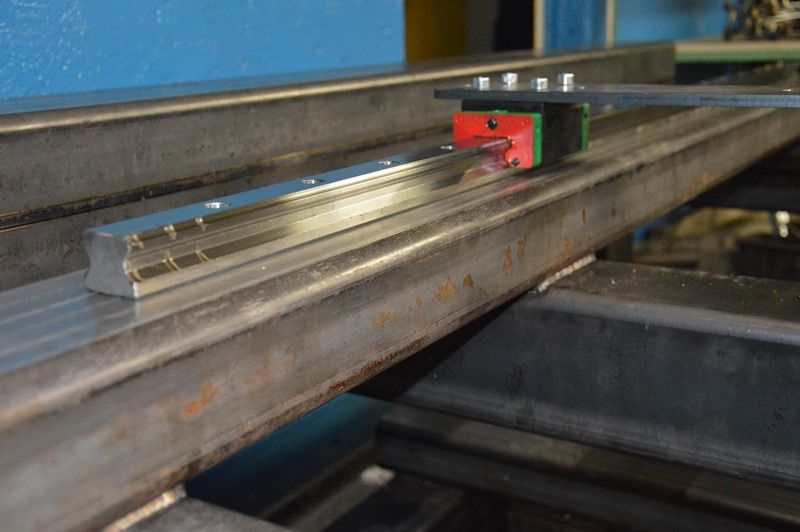

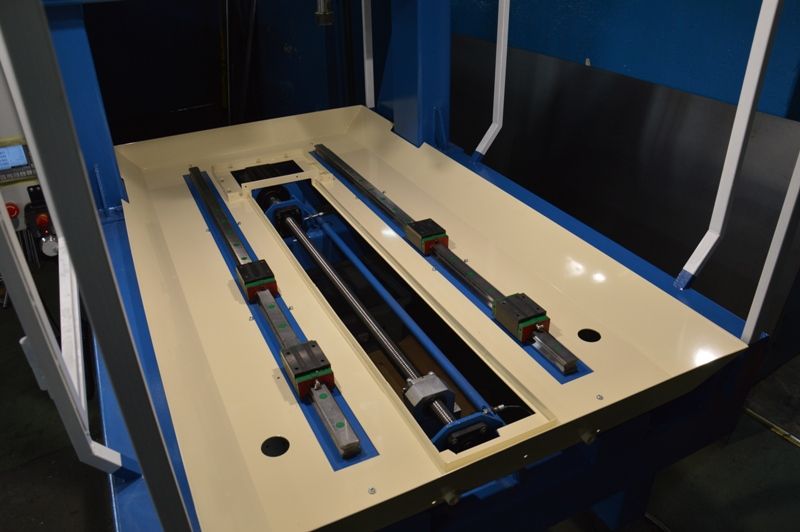

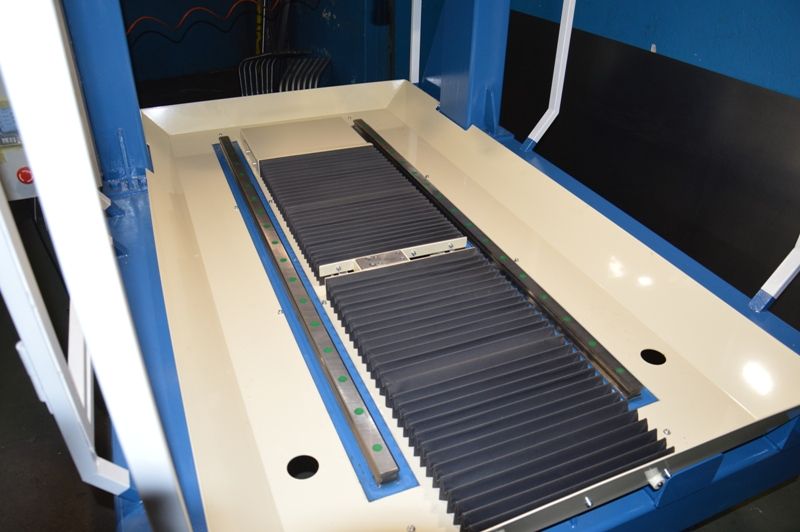

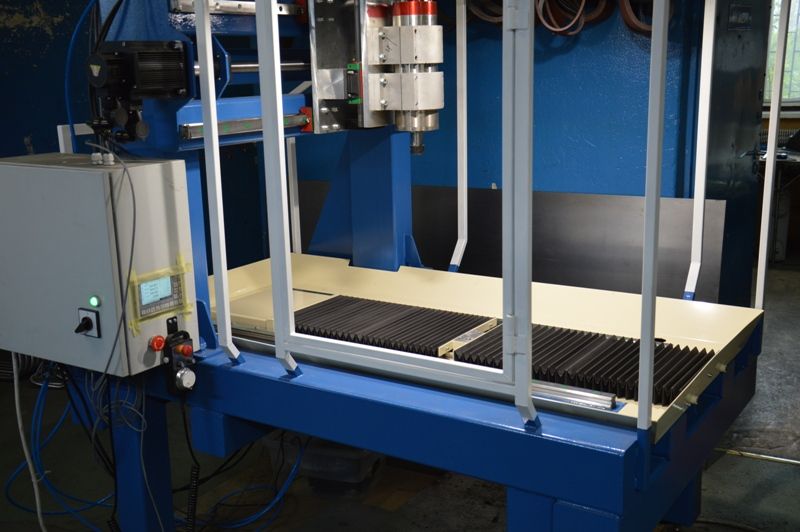

One of the assumptions during the design was to obtain a device with the smallest overall dimensions and at the same time rigid construction. Steel thick-walled profiles were used for this purpose. In fact, design and assembly of the main elements took two months. At the end of December, a skeleton was welded.

After welding, I had to use an external company that evened (milled) the base for linear guides. At this point, it should be mentioned that we are fighting for the accuracy of the machine at the level of a tenth of a millimeter, among other things, which is why it is the most expensive project I have ever done.

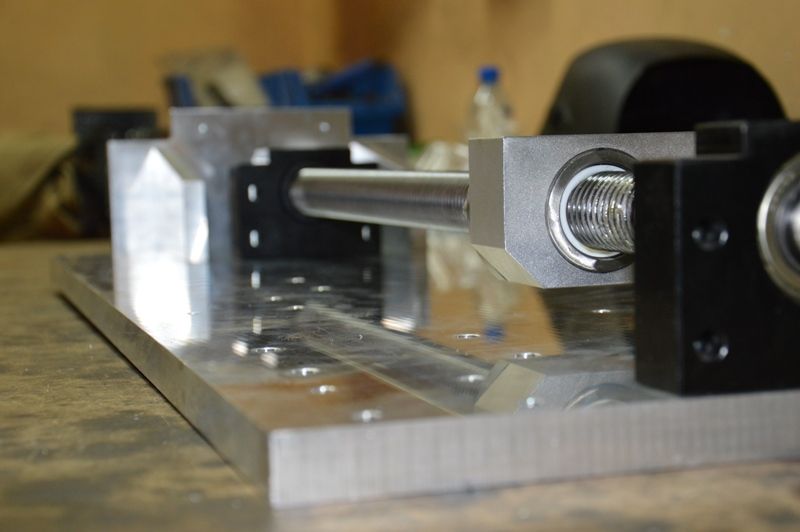

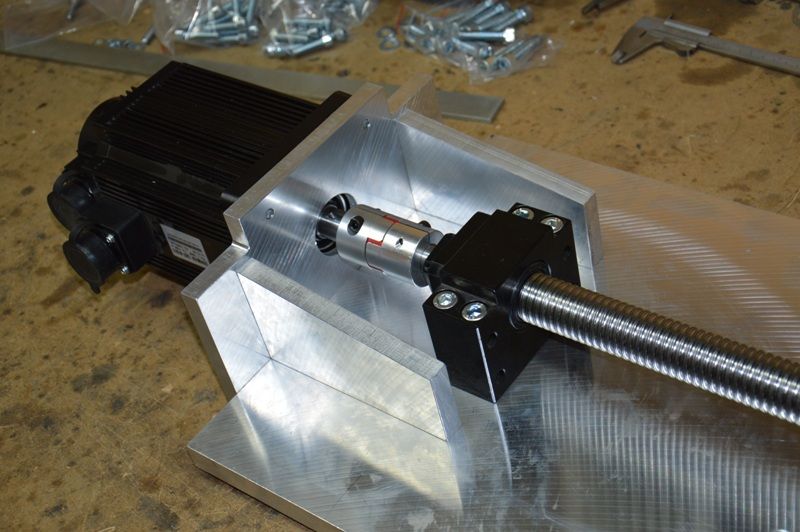

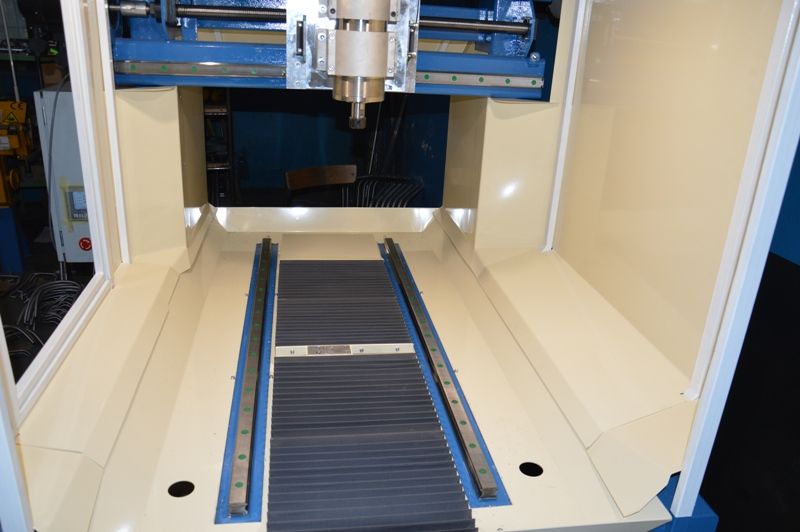

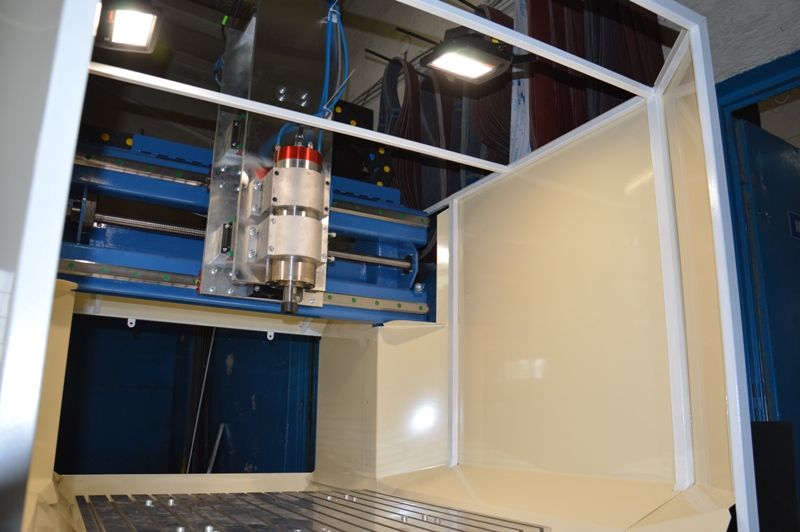

The time has come to make a vertical axis made of aluminum. A few days of milling, turning, mounting, fitting … and the effects can be seen below.

Spindle already in place, pre-ordered cables … you could practically consider the machine finished (or at least ready for testing) … but no, it would be too good. A little work ahead of us 🙂

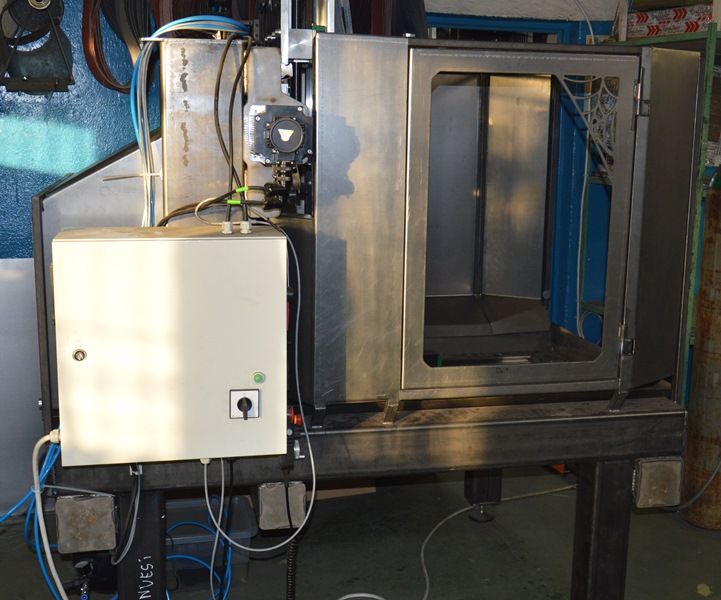

It’s Friday, 10/03/2017. Some new elements have appeared since the last entry, including the housing design. Since Monday, I am getting into the machine’s enclosure, i.e. how to tame the coolant … and a week later the sheets have been bent and matched – the cover is almost ready

After a few months of struggling, the time has come for painting and final assembly

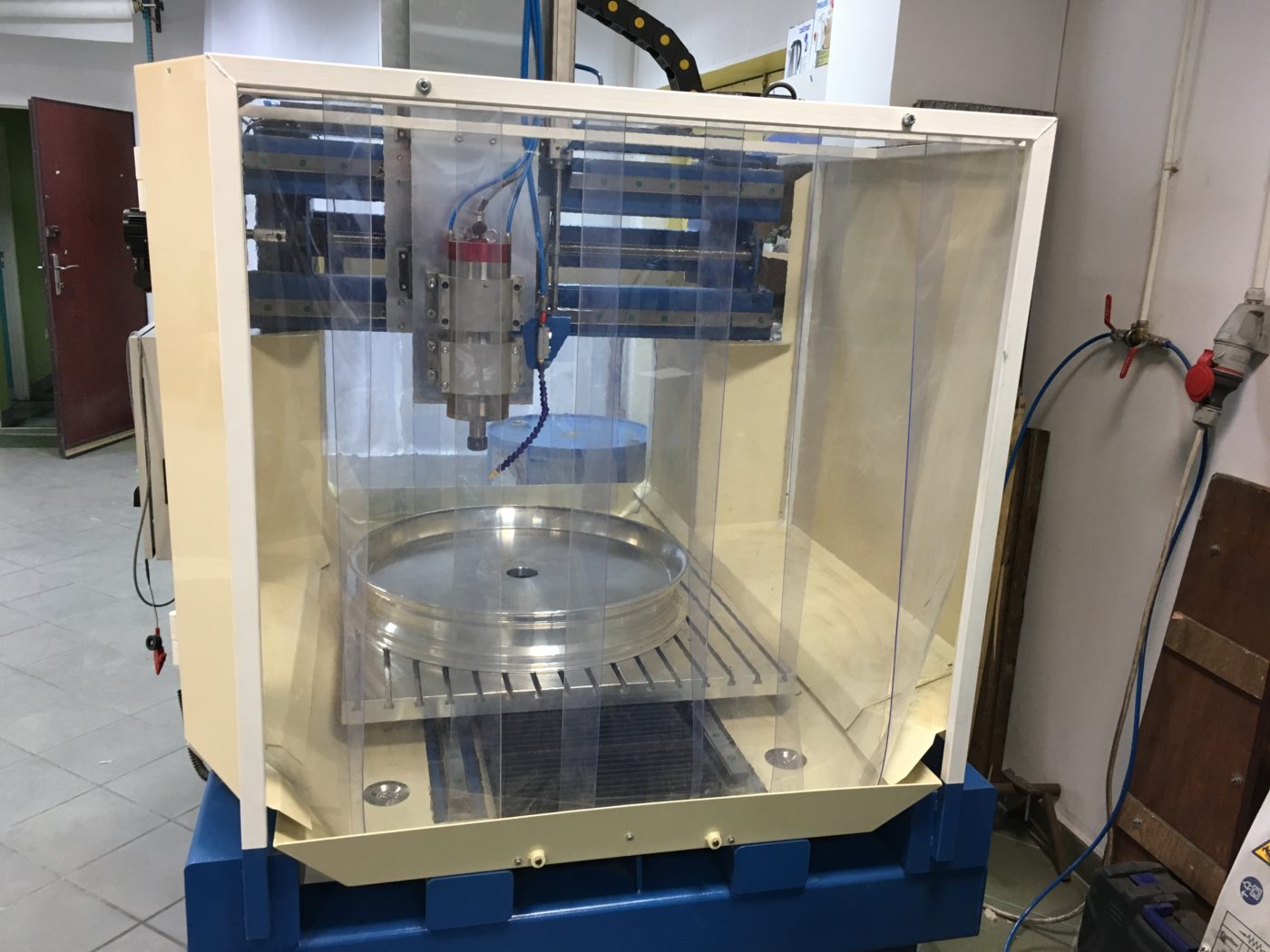

CNC milling machine is ready

We invite you to watch the movie: